Fracture Toughness, JIc

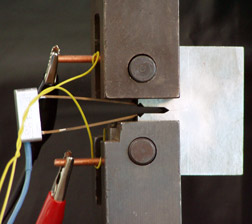

The program provides full machine control and analysis software to calculate JIc to meet requirements of ASTM E 1820, E 1737, E1152, E813, and BS 7448 Part 4. Under crosshead control, the specimen is loaded within rates stated in the standards; load, crosshead position and clip gauge readings are recorded. The original crack length, a0, is estimated from unloading compliance measurements and repeated until the last three values are within 0.2%W. The test is continued with the load/unload sequences to produce J versus crack extension data points evenly spaced over the user prescribed test region.

After the final unloading, the specimen is broken, original crack size and crack extension are measured at 9 equally spaced points, data is checked for qualification. The J versus crack growth behaviour is approximated with a best-fit power law relationship. The blunting line is calculated from material flow properties. The intersection of the power law fit and 0.2 mm offset line parallel to the blunting line defines JIc, provided the validity requirements are satisfied. The results can be displayed either in graphical form or text form. Test data can also be stored as a text file in order to use spreadsheet program facilities.